Revolutionizing Manufacturing: 3D Printed Jigs and Fixtures

- TrueForm Industrial

- Nov 26, 2025

- 4 min read

Updated: Nov 27, 2025

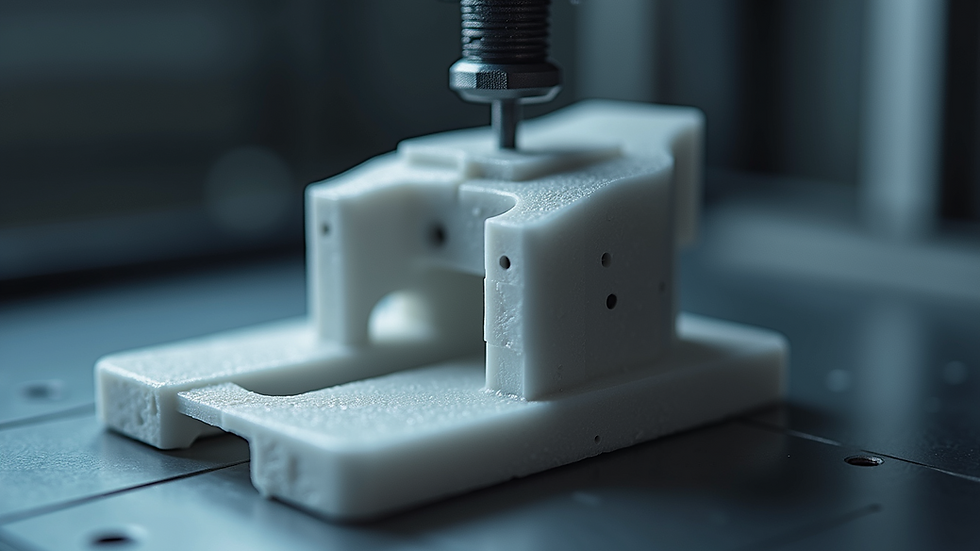

In the fast-paced world of manufacturing, efficiency and precision are paramount. Traditional methods of creating jigs and fixtures often involve lengthy lead times and significant costs. However, the advent of 3D printing is transforming this landscape, offering innovative solutions that streamline production processes. This blog post explores how 3D printed jigs and fixtures are revolutionizing manufacturing, enhancing productivity, and reducing costs.

Understanding Jigs and Fixtures

What Are Jigs and Fixtures?

Jigs and fixtures are essential tools in manufacturing that help to hold and support workpieces during production.

Jigs are devices that guide the tool during machining operations. They ensure that the tool moves in a specific path, enhancing accuracy.

Fixtures, on the other hand, are used to securely hold a workpiece in place. They do not guide the tool but provide stability and support.

Both jigs and fixtures play a crucial role in ensuring that products are manufactured to precise specifications, reducing errors and improving overall quality.

The Traditional Approach

Traditionally, creating jigs and fixtures involves:

Designing: Engineers create detailed designs, often using CAD software.

Manufacturing: The designs are then fabricated using machining processes, which can take days or even weeks.

Testing: After production, the jigs and fixtures are tested for accuracy and fit, which may require further adjustments.

This process can be time-consuming and costly, leading to delays in production and increased overhead costs.

The Rise of 3D Printing in Manufacturing

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital file. It works by layering materials, such as plastic or metal, to build the final product. This technology has gained traction in various industries due to its flexibility and efficiency.

Benefits of 3D Printed Jigs and Fixtures

Speed: 3D printing significantly reduces the time required to produce jigs and fixtures. What once took weeks can now be accomplished in days or even hours.

Cost-Effectiveness: The reduction in material waste and the elimination of complex machining processes lead to lower production costs.

Customization: 3D printing allows for easy customization of jigs and fixtures to meet specific production needs. This adaptability is particularly beneficial for small batch production.

Lightweight Designs: 3D printed jigs can be designed to be lighter than traditional fixtures, making them easier to handle and reducing the strain on machinery.

Complex Geometries: The technology enables the creation of intricate designs that would be impossible or prohibitively expensive to achieve with traditional methods.

Real-World Applications of 3D Printed Jigs and Fixtures

Case Study 1: Aerospace Industry

In the aerospace sector, precision is critical. A leading aerospace manufacturer adopted 3D printed jigs to streamline their assembly process. By using lightweight, custom-designed jigs, they reduced assembly time by 30% and improved accuracy, leading to fewer reworks and lower costs.

Case Study 2: Automotive Manufacturing

An automotive company faced challenges with traditional fixtures that were heavy and cumbersome. By switching to 3D printed fixtures, they not only reduced weight but also improved the speed of their production line. The new fixtures allowed for faster changes between different vehicle models, enhancing overall efficiency.

Case Study 3: Electronics Assembly

In electronics manufacturing, precision is essential for assembling components. A company utilized 3D printed jigs to hold delicate parts in place during soldering. This innovation resulted in a 25% reduction in defects and improved the overall quality of their products.

Challenges and Considerations

While the benefits of 3D printed jigs and fixtures are clear, there are challenges to consider:

Material Limitations: Not all materials are suitable for 3D printing. Manufacturers must choose materials that can withstand the specific conditions of their production environment.

Initial Investment: Transitioning to 3D printing may require an initial investment in technology and training.

Quality Control: Ensuring the quality of 3D printed parts is crucial. Manufacturers need to implement rigorous testing and quality assurance processes.

The Future of 3D Printed Jigs and Fixtures

As technology continues to advance, the future of 3D printed jigs and fixtures looks promising. Innovations in materials and printing techniques are expected to further enhance the capabilities of 3D printing in manufacturing.

Emerging Trends

Integration with AI: The integration of artificial intelligence in design software can optimize jig and fixture designs for specific applications, further improving efficiency.

Sustainability: As manufacturers seek to reduce their environmental impact, 3D printing offers a way to minimize waste and use sustainable materials.

Increased Adoption: As more companies recognize the benefits of 3D printing, its adoption in manufacturing processes is likely to grow, leading to a more competitive landscape.

Conclusion

3D printed jigs and fixtures are not just a trend; they represent a significant shift in how manufacturing processes are approached. By embracing this technology, manufacturers can achieve greater efficiency, reduce costs, and improve product quality. As the industry continues to evolve, those who adapt to these changes will be well-positioned for success in the future.

Incorporating 3D printing into your manufacturing processes may seem daunting, but the potential benefits are immense. Consider exploring how this technology can enhance your operations and keep you ahead in a competitive market.

Comments